Ejectors and Vacuum Systems

Single Stage Vacuum Systems - Ejectors

- Steam Jet Heaters – used to heat liquids by injecting direct steam.

- Thermocompressors – used to increase steam pressure from low to medium using high-pressure steam as motive fluid. Applications such as steam recovery on paper machines and Yankee dryers, heating for evaporation processes and digestors for pulp cooking, etc.

- Vacuum ejectors – used, for example, in evaporation processes or in non-condensing gas aspiration systems to convey gases to combustion systems, NCG Systems.

- Eductors and Tank Mixing Systems – replace mechanical mixers with ejectors that have a longer service life, less maintenance and considerable reduction of electrical energy. They can be applied, for example, to effluent equalization tanks, mixing liquids in storage tanks, etc.

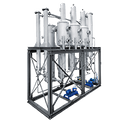

Multi-Stage Vacuum System

- Steam Jet / Hybrid Vacuum System – for processes such as Vacuum Distillation, Oil and Vegetable Oil Refining, Evaporation, Steel Degassing, etc. Can produce vacuum down to 0,01 mBarA.

- Ice Condensation Vacuum System – for Vegetable Oil Refining

- Steam Jet Chiller Plants – use low or medium-pressure motive steam to produce chilled water, for example, to produce chlorine dioxide in the pulp industry.

- Liquid Ring Vacuum Pumps – as stand-alone Vacuum Pumps or in combination with Jet Ejectors for Hybrid Vacuum Systems.

Environmental Solutions

- Jet Aeration – for Waste Water aeration with higher alpha values and lower energy consumption than conventional diffuser technology – see the video on the left

- Liquid Jet Gas Compressors – for Water Treatment using ozone for disinfection for potable water production.

- Jet and Venturi Scrubbers – for Waste Gas Cleaning and Dedusting

- Caustic Recovery Plants – recover mercerizing lye in cotton and denim textile finishing processes producing recovered strong lye, hot water, and hot condensate.

About Koerting Hannover GmbH:

Körting has established itself as a leading manufacturer of vacuum engineering products and environmental technology. The focus on engineering and key competencies in niche markets worldwide makes the company an important partner in the processing industry. In the ejector/vacuum technology and waste gas cleaning/environmental technology segments, assignments are analyzed and energy-efficient customized solutions are drawn up and implemented.

The demand for integrated solutions, combined with close customer collaboration, encourages us to consistently develop our products and services. New, innovative opportunities are enabled through a partnership with the worlds of science, research and business. Application-driven research constantly provides the new stimuli required to deliver cutting-edge Körting technology. Körting Hannover AG harnesses its in-depth expertise to deliver future-proof, customer-centric applications and solutions.

With subsidiaries in Brazil, China, India, Malaysia, Poland and Russia, Körting is never far away from its international customers. Körting’s Hans Hennig GmbH subsidiary in Ratingen near Düsseldorf offers a full range of expertise on process heat/firing technology.

Körting Research and Development

When it comes to its products, Körting Hannover GmbH makes no compromises on quality. As a manufacturer of leading vacuum and environmental technology, application-driven research and development are required. These are the cornerstones for the consistent enhancement of products and services. And they are pivotal to launching new technical solutions.

Development Projects

Every day Körting development engineers and technicians work towards optimizing existing products and developing new solutions. Furthermore, as highly-trained specialists, they solve problems and eradicate malfunctions in existing systems. Our experts operate around the world, so they are constantly in tune with customers’ needs and know the products inside out. And this experience is part and parcel of the development work they do.

Sophisticated equipment

Körting’s research and development team have sophisticated equipment so that it can implement new projects with the necessary degree of innovation. Test rigs and facilities for virtually all Körting products and components are important for quality control purposes. Testing equipment for enhancements and adaption to special conditions is also available. Trials are often carried out on the customer’s own premises and the resulting operating data is recorded and analyzed. In conjunction with remote monitoring of processes, this data guarantees Körting products are constantly being refined. Körting’s own pressure and temperature calibration lab with Dakks/DKD certified measuring devices ensures that the data is captured to reflect real-world conditions. The results of these in-depth services benefit customers directly.

Computer-aided Development

The stringent demands placed on our own development are achieved with the help of computer-aided systems for capturing measurements. Simulation tools for computational fluid dynamics (CFD) allow the development of customized process-engineering solutions and special customer requests. Körting uses in-house design programs to process problems specified by the customer. The database and software development of these programs is firmly anchored in Körting Hannover AG’s development activities.

Manufacturing at Körting – Quality “Made in Germany”

Combined with more than 140 years of experience and worldwide engineering competence, Körting Hannover GmbH places high demands on the quality of its own manufacturing. In terms of optimal customer orientation, high-quality materials of the most modern fabrication technologies are applied. Concentration on core competencies allows thereby for a well-directed orientation towards improving processes. Continuous further training of qualified personnel provides for ultra-modern manufacturing processes which play a large part in the quality of Körting products. In the close connection between manufacturing and testing, Körting creates optimal prerequisites for the highest quality and reliability.

Own Testing Facilities

Amongst others, the company disposes over testing facilities for the near-service testing of ejectors and condensers. So, therefore, products manufactured at Körting leave the works only after they have been successfully tested for function.

With diverse testing stands in the firing and environmental technical center, complex firing processes and flame guiding as well as subsequent flue gas scrubbing can be adjusted to the respective customer tasks separately as well as in the form of a total system. The components and units of the test stands offer thereby the variability of testing this in a scientific and practical manner. These testing stands do not only play a large part in the inspection and monitoring of our own quality. Without them, the continuous development of our own products and technologies just would not be possible.

Quality Assurance

Körting manufactures at the Hannover location and supplies thereby components for process engineering “Made in Germany”. The Quality Management System caters for checking of the processes on a permanent basis. Each and every company department has been integrated into this process and contributes towards this success and extensive customer satisfaction. The certifications which Körting has acquired are the recognition of this readiness for action and demonstrate the high work standards of all company departments.

Certifications (Excerpt)

- DIN EN ISO 9001 : 2015

- Manufacturer in acc. with AD 2000 – Leaflet HPO in connection with DIN EN 729-2

- CE 0045 according to directive 2014/68/EU

- ASME-U-Designator-Certificate

- Manufacture License of Special Equipment China Level A1

- TR CU Zertifikate (Russia, Belarus, Kazakhstan)

- UkrSEPRO (Ukraine)