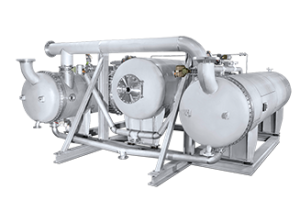

ICE Condensation Vacuum Systems

Ice condensation to generate vacuum when refining edible oil

In an era of rising energy costs and stringent environmental regulations, the Körting ICE Condensation Vacuum System is the number one choice for creating vacuums when refining or deodorizing edible oil. A high degree of plant availability, substantial energy savings and minimal harm to the environment ensure low running costs. Edible oil manufacturers and OEMs worldwide choose cutting-edge, reliable technology from Hannover in Germany.

Benefits of Körting ICE Condensation Vacuum System

- first-class product quality due to optimum vacuums

- a reduction in the energy costs of the whole process (less motive steam needed)

- lower cooling water requirements

- much lower running costs compared with other vacuum systems

- eco-friendly operation (little waste air and waste water)

- high levels of reliability and availability

- easier cleaning and maintenance

- multi-purpose use for physical refinement and deodorisation of all edible oils

- customisable design of the vacuum system

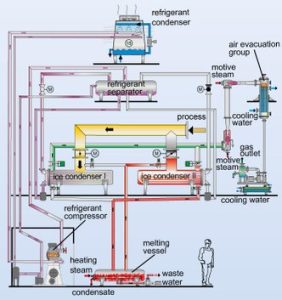

How they work

Just like all vacuum systems used to produce edible oil, Körting ICE Condensation Vacuum Systems can generate a process vacuum of 1 – 4 mbar. In contrast to traditional vacuum systems, Ice Condensation systems enable the process steam to condensate at process pressure. Because at processing pressure of 1 mbar for example the condensation temperature is -20°C, a cooling agent is required in the condenser pipes that will function at -30°C.

The process steam will then settle as a layer of ice on the condenser pipes. This direct transformation from the vapour to the solid phase is called desublimation. The condenser must be defrosted regularly to remove the layer of ice. Körting ICE Condensation Vacuum Systems have two ice condensers so that the system can continue operating without any downtime or idle periods. While one condenser is being cooled and the process steam is desublimated, the other ice condenser is defrosting. Vacuum steam is used to quickly, carefully and effectively melt the ice layer. The cycles are designed in such a way that there is no negative impact on the stability of the vacuum during the swap-over.

Virtually no pollutants or harm to the environment

Strict separation of the cooling water and condensate avoids pollutants and harm to the environment. Due to condensation at processing pressure and low temperature, the condensate stays pure and highly concentrated. Almost 100 % of the oil components suctioned off with the process steam (e.g. traces of fatty acids) are encountered in the condensate again.

Only a few substances with lower boiling points, like aldehydes and ketones, are removed using steam jets from the ice condensers along with the non-condensable gases and then condensed in a surface condenser. Therefore any contact with the cooling water can be ruled out. The non-condensable gases from the process and the leakage air are polluted with the oil substances that have low boiling points. This gas mixture is the only waste gas flow that leaves the vacuum ejector at the outlet connection to the downstream liquid ring vacuum pump. It can then be burnt or treated in biological filtering equipment.

Körting ICE Condensation Vacuum Systems cut costs

A comparison of the running costs of ice condensation machinery with traditional systems for edible oil products underscores the savings potential of ice condensation:

- due to the drastic reduction in steam consumption, operating Körting ICE Condensation Vacuum System is much cheaper than traditional vacuum systems

- the saving on running costs quickly compensates for the higher investment costs for an ice condensation system; the higher the output, the quicker the return on investment of an ice condensation plant

Compare the costs for yourself!

Körting Hannover AG and Erivac Konsult AB has provided a comparison of the costs of various edible oil deodorization systems. We would be happy to give you detailed information on possible savings potentials on request.