Industrial Vacuum Pumps

Industrial vacuum pumps are a fundamental part of many industrial processes and are used to create and maintain vacuum in various applications. These pumps play a crucial role in a variety of industries, such as petrochemical, chemical, pharmaceutical, pulp & paper and food processing, etc. They can be used for processes involving filtration, evaporation, distillation, absorption, freeze-drying, drying, degassing, etc.

What is an Industrial Vacuum Pump?

An Industrial Vacuum Pump is a device used to remove gases from a container, reactor or closed system to create a vacuum. It works by sucking in the gases and diverting them from the desired area, resulting in reduced pressure inside the system.

There are different types of vacuum pumps and which one works best for each process or application depends on the conditions of the individual process, pressure, desired vacuum in the process, temperature, corrosion and erosion resistance, clean or dirty gas flows, cost of drive media, etc.

Mechanical Vacuum Pumps / Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps are mechanical industrial vacuum pumps that use electricity to create a vacuum. They have low operating costs due to the electrical motor and mechanical compression. They are found in many process engineering applications. In addition to the standard range, Koerting can offer a variety of customized solutions on request.

Advantages

The benefits of using Koerting liquid ring vacuum pumps:

- Customized design of hybrid systems with jet ejectors, condensers and liquid ring vacuum pumps.

- designs adapted to the process concerned

- oil-free compression (no contamination of the product)

- Ability to resist most liquids, vapors and solids (with small grain size).

- ATEX compliant construction is possible

- As an independent system supplier, Koerting can choose between different components from different manufacturers.

JetPumps

Jet pumps, jet vacuum pumps, or Ejectors, are sophisticated empirical engineering solutions, industrial vacuum pumps, that utilize gas or most often steam as a driving medium instead of electricity. This is by utilizing the Venturi principle, the reduction in pressure of a media as its velocity increases when passing through a smaller cross-section, to create an effective vacuum and handle process gases in various industrial applications.

JetVacuumSystem

When deeper vacuum is required, a combination of devices in series is needed. Often, series-connected jet pumps / ejectors in combination with condensers are used to design these vacuum systems for the best possible energy efficiency and process reliability.

Advantages of JetPumps and JetVacuum systems

Cost efficiency and low maintenance: With low initial costs and minimal maintenance, our jet pumps are an economically advantageous solution compared to other vacuum pumping technologies.

Flexibility and adaptability: Whether for extraction, evacuation or general vacuum service, our pumps can be tailored to meet specific needs and requirements in different industries and sectors. They can handle large gas volumes in relatively small designs.

Simple design and reliable operation: With their simple and streamlined design, with no moving parts to wear out or break, our ejectors offer reliable operation and minimal maintenance and low maintenance costs.

High Operating Reliability: Steam ejectors can perform very well and create high-efficiency vacuum conditions even in very difficult operating conditions.

Wide range of construction materials: Steam ejectors can be made from virtually any material and therefore a specific corrosion- or erosion-resistant material can be chosen.

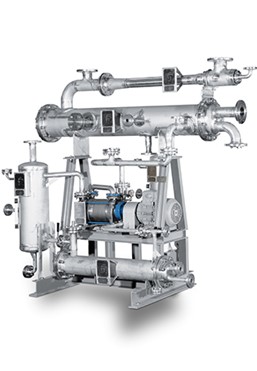

Hybrid Vacuum System

Sometimes the best, most energy-efficient solution with the lowest operating cost can be a combination of mechanical vacuum pumps, Liquid Ring Vacuum Pumps, and Jet Pumps / Jet Vacuum Systems.

Technical expertise and tailored design options

Koerting vacuum pumps are designed to meet specific requirements, with suction pressures down to 0.05 mBar absolute and suction flows down to 0.5 kg/h. With Erivac and Koerting’s combined technical expertise and tailored design options, high availability, reliable operation, minimal maintenance and the lowest energy consumption on the market are guaranteed.

Efficiency and low energy consumption

With a focus on low steam and energy consumption, Koerting vacuum pumps offer cost-effective solutions for industrial processes. Their systems are designed to maximize efficiency and reduce operating costs over time.

Multistage Jet vacuum pumps for optimal performance

Koerting multistage steam jet vacuum pumps are designed for robust and maintenance-free operation. These vacuum pumps offer almost unlimited application possibilities and high reliability, making them a popular choice in the industry.

Controllable systems for customized operation

With the ability to equip its vacuum pumps with control units, Koerting can tailor the system to adapt to varying operating conditions. This means reduced energy consumption and optimal performance in all situations.

Environmental protection and sustainability integrated into the design

Koerting vacuum pumps are not only efficient but also environmentally friendly. By offering integrated solutions for environmental protection and sustainability, they are at the forefront of meeting the industry’s high demands for efficiency and environmental friendliness.