Jet and Venturi Scrubbers

Jet and Venturi Scrubbers for waste gas cleaning

As a result of increasing environmental regulations of the legislator, plant operators are forced to clean the exhaust air of their processes. Körting jet and venturi scrubbers meet the ever-increasing requirements for gas cleaning worldwide. For decades, they have been used successfully for cooling, physical and chemical absorption and dedusting. Compliance with emission regulations is possible thanks to Körting technology.

Körting Jet Scrubber

Jet scrubbers are used for: Cooling – absorption – dedusting – conveying. The self-priming jet scrubber is superb for removing dust with particles over 3 μm in size.

Applications

The self-priming jet scrubber is superb for:

- conveying gas without mechanical ventilators

- direct gas cooling (quenching)

- physical and chemical absorption of harmful substances (SO2, Cl2, HCI, NH3, HF, H2S, etc.)

- removing dust with particles over 3 μm in size

- recovering substances from gases

Körting Venturi Scrubber

Venturi scrubbers are mainly used for: Dedusting

The Venturi scrubber is ideal for removing dust with particle sizes less than 3 μm.

Applications

Wet operation enables separation of dust in the following cases:

- where the dust has critical characteristics, i.e. it’s hygroscopic, swells or is sticky, which rules out dry separation in bag filters

- after drying systems

- when it comes from steam systems with a hot condensate as scrubbing liquid

- after firing processes (e.g. soot) where the hot flue gas is cooled at the same time

- when it arises from filling, mixing or agitating systems

Jet Scrubbers

Jet scrubbers are used for the following basic processes:

Cooling – Absorption – Dedusting – Conveying

The gas enters the jet scrubber from the side. The motive fluid acts as a scrubbing medium and direct current injects it into the gas and into the scrubber. The gas is accelerated due to the impulse exchange with the motive fluid. This results in conveying flow enabling an increase in the gas pressure. Depending on the design of the plant, this rise in pressure means that the internal flow resistance of the plant and the resistance in adjacent pipes can be overcome. Therefore, the jet scrubber replaces a mechanical ventilator in many cases.

The level of power transmission manifests itself in a jet scrubber’s pressure gain. Because the scrubbing medium is sprayed through nozzles, the cylindrical section of the scrubber is filled with a full cone and reaches the large phase interface area between the gas and the liquid which is required for the basic operations.

Advantages of Körting jet scrubbers

- simple designs

- little maintenance required

- high levels of reliability and availability

- no fire risk in the scrubber

- a combination of gas conveying with dedusting and absorption

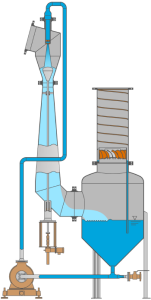

A typical Körting jet scrubbing plant consists of:

- jet scrubber

- separation tank

- swirl droplet separator (DTA)

These components all play a part in the process as a whole. The jet scrubber conveys, absorbs, dedusts and cools the gas with the aid of the scrubbing medium. The scrubbed gas and the liquid phase are separated from one another in the separation tank. At the same time the tank acts as a buffer before the scrubbing liquid is distributed. The downstream swirl droplet separator is used to separate the fine droplets caught in the gas flow. Depending on the engineering requirement, further components can also be added. Environmental regulations are complied with and substances can be recovered from gases by using single or multi-stage jet scrubbers, also in combination with packed towers.

Sizes

The Körting jet scrubbing plants are supplied as follows:

- as standard versions of DN 80 to DN 1000 for gas flows of 60 to 26000 m³/h, also in combination with packed towers

- customized solutions for gas flows of 60 to 100000 m³/h, in single or multi-stage designs

Depending on the application, combinations can be used to fulfill special conditions and requirements. Solutions with good track records are also available for special cases, such as gas flows of up to 300000 m³/h or gas temperatures over 1000 °C.

Materials

- carbon steel, stainless steel

- steel with coatings: rubber, PVDF, PTFE, Halar, etc.

- plastics: GFK, PP, PVC, PVDF reinforced and non-reinforced

- special materials

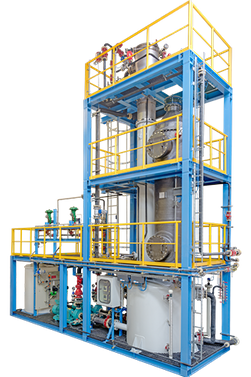

Vent Gas Treating System (VGTS)

The Vent Gas Treating System is a complete unit that includes jet scrubber, separation tank, packed tower and swirl droplet separator and is fully mounted in a steel structure. The objective of the system shown is to remove hydrochloric acid, chlorine and sulphur dioxides from a hot processing flow. The plant is designed for gas inlet temperatures of 530 °C. By using caustic soda (10% NaOH) and sodium hydrogen sulphite (20% NaHSO3) as scrubbing fluids all absorbed components can be removed from the waste gas. As required by statute (German TA Luft regulation) the gas emissions are scrubbed and can be released into the atmosphere.

Venturi scrubbers

Venturi scrubbers are mainly used for:

Dedusting

The gas enters the scrubber from the side or from the top. In the same direction of flow as the gas, the liquid is injected into the scrubber through a single nozzle or an evenly spaced array of nozzles at the top. The combined flow is then massively accelerated because it’s directed through the steadily narrowing Venturi throat. In contrast to the liquid drops, the gas and the dust particles quickly reach speeds of up to 150 m/s. Very high relative speeds between the gas and liquid occur.

The resulting shearing forces break up the liquid drops into tiny droplets. At the same time, due to their inertia, the dust particles will no longer be able to follow the flow of the gas. They are hurled onto the droplets and separated out as a result. The energy that has to be transmitted in order to generate relative speeds manifests itself in the pressure consumption of the Venturi scrubber. This is compensated for by a mechanical blower.

The Venturi scrubber that doesn’t actively convey the dust is ideal for removing dust with particle sizes less than 3 μm.

Advantages of the Körting Venturi scrubbers

- their designs are simple and compact

- little maintenance is required

- they offer high levels of reliability and availability

- there is no fire risk in the scrubber

- investment costs are low

A typical Körting Venturi scrubbing plant consists of:

- Venturi scrubber

- separation tank

- swirl droplet separator (DTA)

The Venturi scrubber separates gas and dust particles. The purpose of the separation

tank is to separate the scrubbed gas and the liquid phase and to act as a buffer before

the scrubbing liquid is distributed.

The downstream swirl droplet separator is used to separate the fine droplets caught in

the gas flow. Depending on the engineering requirements, further components can

also be added.

Sizes

The Körting Venturi scrubbers are only supplied as customized solutions for gas flows of 1000 to 125000 m³/h, in single or multi-stage designs

Materials

- carbon steel, stainless steel

- steel with coatings rubber, Halar, etc.

- plastics: GFK, PP, PVC, PVDF reinforced and non-reinforced

- special materials

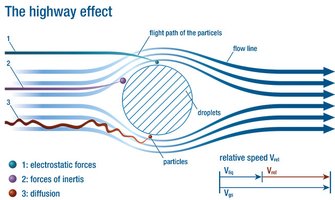

The highway effect

The separation efficiency of the Venturi scrubber is gauged by the pressure consumption of

the gas. This is proportional to the relative speed. The higher the relative speed and therefore

the pressure consumption too, the smaller the size of dust particles that can be separated.

This process is comparable with flies getting caught on a car windscreen on the motorway.

The higher the speed of the vehicle, the smaller the size of the flies that are caught on the

windscreen. This is why this process is called the highway effect.

Dedusting and fractional degrees of separation

Dedusting depends on:

- the diameter and density of the particles

- the number and diameter of the droplets

- the relative speed between the droplets and particles.

The greater the density of the dust, the diameter of the particles, the relative speed to the droplets and the greater the number of tiny droplets, the better the separation. For a known distribution of particle sizes and a desired degree of separation, the energy required (by the fan) can easily be identified. However, for an unknown distribution of particle sizes this is not possible. In this case, further on-site analysis is required in order to get a clearer idea of the particle size distribution.