Plate heat exchangers

Industrial Plate Heat Exchangers

An important component in heat transfer technology and heat recovery is the plate heat exchanger. This device is used to efficiently transfer thermal energy between two different media. Plate heat exchangers have become an indispensable part in a wide range of sectors and industries due to their ability to improve energy efficiency and reduce operating costs.

What is a plate heat exchanger?

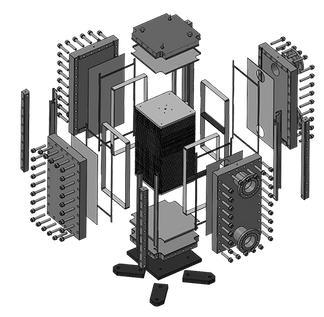

A plate heat exchanger is a device used to transfer heat between two media, usually liquids or gases, without them mixing. This type of heat exchanger consists of several corrugated, corrosion-resistant, plates, usually made of stainless steel. These plates are arranged in parallel and separated by seals, creating multiple channels for the media to be heat exchanged.

In cases where the seal between plates consists of elastomeric/plastic materials such as NBR, PTFE, etc. we have so-called – Gasketed Plate Heat Exchangers.

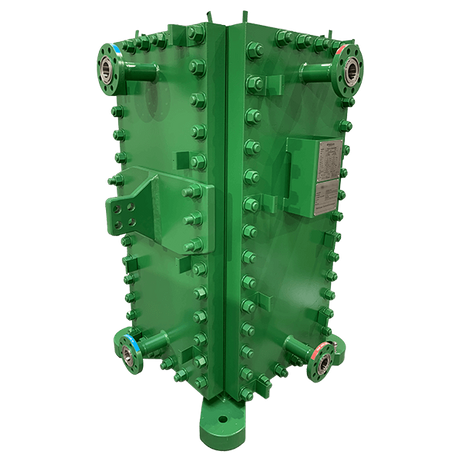

When the temperature and or pressure gets a little higher, the elastomeric/plastic materials can no longer withstand the loads they are exposed to and thus must be replaced by e.g. soldering or welding. Erivac offers in these cases – Welded Plate Heat Exchangers.

Function and benefits

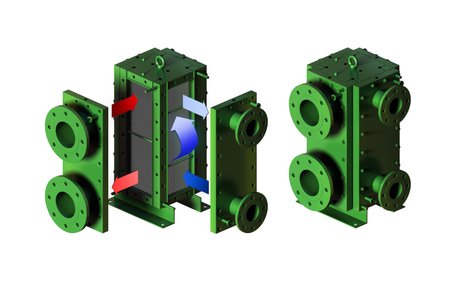

Plate heat exchangers work on the principle of conduction, where heat transfer occurs through indirect contact between the hot and cold media. As liquids or gases flow through the separate channels, the heat energy from the hot medium will be transferred through the walls of the corrugated plates to the cold medium. This allows an efficient and rapid transfer of heat without significant energy losses.

One of the main advantages of plate heat exchangers is their compact and efficient design. The large surface area of the corrugated and relatively thin plates provides a significantly higher heat transfer coefficient than traditional heat exchangers such as shell & tube heat exchangers, resulting in improved efficiency and a smaller heat exchanger surface area. Plate heat exchangers also have a very compact design with a large heat exchange area per unit volume. This means that if a plate heat exchanger and a traditional shell & tube heat exchanger are designed for exactly the same application, the plate heat exchanger will: – be many times smaller; – have much lower weight; – and usually have a lower price. In addition, plate heat exchangers are relatively easy to maintain if the media is reasonably clean, as the plates can be cleaned if necessary.

Areas of use

Plate heat exchangers are widely used in various industries, where they meet specific needs for heat regulation, heat recovery and energy efficiency.

Here are some examples of industries where plate heat exchangers are used:

- Biofuels and edible oils;

- Carbon Capture;

- Chemical industry;

- Food industry;

- Mining and Steel industries;

- Petrochemical Industry;

- Petroleum Refineries;

- Thermal Power Plants;

- Pulp and Paper Industry;

- Textile industry.

Plate heat exchangers are indispensable in many industries, where they enable the efficient transfer of thermal energy between different media. Their compact design, high efficiency and relatively easy maintenance make them an attractive choice for companies seeking to improve energy efficiency and reduce operating costs. Whether in HVAC, process industry, food industry or oil and gas industry, plate heat exchangers play an important role in meeting the specific requirements of each industry and contribute to sustainable and efficient operations.

What is the principle of conduction?

The principle of conduction is an important mechanism of heat transfer that occurs when there is a temperature difference between two materials in direct contact. In conduction, the heat energy is transferred from the higher temperature region to the lower temperature region through molecular interaction.

In a solid material, the atoms or molecules are tightly packed and are in constant motion. When a part of the material is heated, the thermal energy of the atoms or molecules in that area increases. These energy-rich particles collide with nearby particles and transfer their energy to them. This creates a chain reaction where the energy is gradually transferred from particle to particle through the material.

The thermal energy is transferred by the particles transferring kinetic energy to their surroundings. This means that the energy-rich particles collide with the surrounding particles and transfer the energy through these collisions. In this way, the thermal energy spreads from higher-temperature regions to lower-temperature regions within the material.

The thermal conductivity of a material depends on its properties, such as density, specific heat capacity and thermal conductivity. Materials with high thermal conductivity, such as metals, have the ability to transfer heat efficiently, while materials with low thermal conductivity, such as insulators, limit heat transfer.

The principle of conduction is used in heat transfer applications and technologies, including plate heat exchangers. In a plate heat exchanger, the heat energy is transferred from one media to another by conduction through a plate, enabling efficient heat transfer without mixing the media.