Thermocompressors

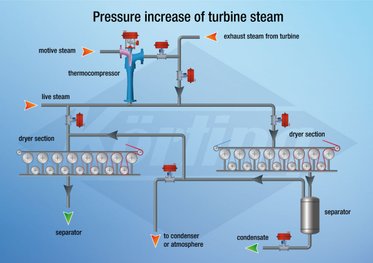

Improvement of energy efficiency to reach lower operational costs and environmental impact is of key importance to industries all over the world today. Thermocompressors, sometimes also called Thermal Vapour Recompressors – TRVs -, can be of significant importance for efficient use us steam. This ingenious device utilizes the principle of combining a high-pressure steam with a low-pressure steam to increase pressure and achieve a resulting steam with a medium-pressure steam, somewhere between the high-pressure motive steam and low-pressure suction side steam. Thus, low-pressure steam can be compressed and utilized at higher pressure and temperature in a more efficient way in applications where the low-pressure steam would not be suitable. Often waste steam can be compressed, using thermocopressores, thus avoiding unnecessary energy waste.

What is a thermocompressor?

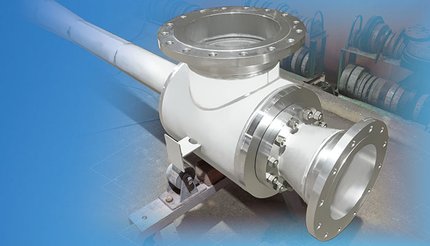

A thermocompressor is a device used to compress steam by utilizing the principle of combining high-pressure motive steam with low-pressure steam. By releasing high-pressure steam through a motive nozzle pressure energy is transformed to kinetic energy while simultaneously lowering the pressure at the nozzle outlet, the low-pressure steam is drawn into the thermocompressor. The two flows are combined in the diffusers, where the kinetic energy of the high-pressure steam is transferred to the low-pressure steam and transformed back to pressure energy resulting in a pressure increase of the low-pressure steam. The compressed discharge steam can then be used again at a higher pressure level, than the low-pressure steam, in various processes.

Advantages of Thermocompressors

The advantages of thermocompressors include the ability to control the steam flow without affecting the motive pressure, providing flexibility and energy savings. Thermocompressors are used in various industries and applications, including increasing steam pressure in low-pressure networks, evaporating processes, pulp manufacturing, pulp drying and operating paper machines.

By utilizing thermocompressors, it is possible to effectively compress steam and achieve the desired pressure level in various processes, resulting in improved efficiency and energy savings as well as reduced environmental footprint.

Due to how thermocompressors are designed, they have the following advantages:

- Thermocompressors are simple, relatively compact and lightweight constructions. Thus, they are easy to install in a process and often with minimum changes in existing pipework.

- Investment cost is relatively low and payback time can be very short. Operational costs are very low due to minimum maintenance and spare part necessity.

- There are no moving or rotating parts for fixed-type thermocompressors and few moving parts for adjustable ones, thus wear is low and spare part necessity is also low.

- Minimal maintenance is needed, as there are no or few moving parts, thus the units can be installed in remote places or locations.

- Different than Mechanical Vapour Recompression (MVRs), thermocompressors (TVRs) have an oil-free discharge which ensures there is no lubrication contamination.

Benefits of controllable nozzle needle

To increase the flexibility and range of applications for thermocompressors, there are controllable versions that have adjustable nozzle needles. This makes it possible to change the motive steam flow without affecting the motive pressure. In partial load situations, this offers significant advantages in terms of motive steam consumption compared to a solution that requires a separate control valve to lower the motive pressure.

Applications for thermocompressors

Thermocompressors are used in various applications where the compression of steam is required to achieve the desired pressure or to optimize processes. Here are some examples of applications for thermocompressors:

- increasing steam pressure in low-pressure networks: Thermocompressors can be used to increase steam pressure in low-pressure networks. By compressing the steam, it can be delivered at a higher pressure and thus effectively used in various processes.

- Evaporation: In industries using evaporation, such as in the production of chemicals, pulp industry, or food products, etc., thermocompressors are used to compress low-pressure steam from the evaporation for use as heating steam and thus increase the efficiency of the evaporation process.

- Pulp Cooking or Digesters Process: In the pulp industry, thermocompressors are used for cookers or digesters to compress low pressure steam to a higher discharge pressure and temperature for more energy efficient digestion of wood chips to pulp.

- Pulp Dryers: Thermocompressors can be used at Pulp Dryers to increase steam pressure and thus the efficiency of the Drying process. With increased steam pressure from the Thermocompressor often also the production capacity of the drier can also be increased.

- Paper and Board Machines: In the paper and board industry, thermocompressors can be used to compress the steam used for Paper and Board machines, especially for Yankee Dryers, Cylinders, Steam Boxes, etc., thereby optimizing the efficiency of the process.

- Condensate Receivers: In the process industry condensate receivers often release steam to the atmosphere, wasting the remaining energy in this low-pressure steam. With a thermocompressor this waste steam can be compressed for use once more in the process increasing energy efficiency.

- Exhaust Steam Lines: Older process industries often had exhaust steam lines, with a loss of energy to the atmosphere as a result. As for condensate receivers, these low-pressure steam flows can be recompressed for use in heating for example.

Conclusion

Thermo-compressors are an efficient and flexible technology to compress steam and achieve the desired pressure in various applications. By utilizing the principle of combining high-pressure steam and low-pressure steam, thermocompressors can offer significant benefits, such as reduced overall consumption of steam and energy and increased process efficiency. Whether it is increasing steam pressure in low-pressure networks, optimizing evaporation processes, or improving the pulp and/or paper industry’s manufacturing processes, reuse of waste steam, etc., thermocompressors play an important role in meeting specific needs and contributing to energy efficiency and reduced environmental footprint.