Tubular Heat Exchangers – Shell & Tube Heat Exchangers

An efficient solution for heat transfer in different industries

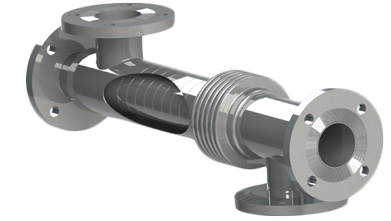

Tubular Heat Exchangers and Shell and Tube Heat Exchangers are important components in heat transfer technology used to efficiently transfer heat between two media. These types of heat exchangers consist of one tube or several tubes in a bundle inserted in a shell. The tubes are usually straight, u-shaped or spiral wound. One of the medias flows on the shell side while the other media flows in the tubes. This allows an efficient heat transfer between two media without mixing them.

Tubular Heat Exchangers and Shell and Tube Heat Exchangers can be designed in many different ways to be used in virtually any type of industrial application with the correct choice of type, material and corrosion resistance, temperature and pressure resistance, etc. In the food industry, for example, we often see Tubular Heat Exchangers for low pressures and temperatures, with requirements for polished stainless-steel materials for high product safety. In oil and gas applications, Shell and Tube Heat Exchangers are used where pressures and temperatures can be very high, up to 150 bar and 550°C, then Shell and Tube Heat Exchangers are one of the few solutions available.

Erivac can offer Tubular Heat Exchangers as well as Shell and Tube Heat Exchangers for this entire spectrum, from smaller units at low pressure and temperature to equipment for applications at extreme pressures and/or temperatures. Most commonly, we offer solutions with corrugated tubes for increased turbulence and thus better heat transfer coefficients. Corrugated tube heat exchangers are also particularly effective for viscous/pasty media such as digester sludge and food products etc. More about – Corrugated Tube Heat Exchangers.

For Large Scale applications as LNG and Natural Gas Industries, Petroleum Refineries and Petrochemical Industries etc. where very large heat exchangers are needed at very high pressures and/or temperature we can also provide Coil Wound Heat Exchangers,

When are Tubular Heat Exchangers used and which industries benefit from them?

Tubular heat exchangers are used in a variety of applications and industries where heat transfer is necessary. Here are some common uses:

- Biofuels and cooking oils;

- Generation of biogas;

- Chemical industry;

- Food industry;

- Mining and steel industries;

- Petrochemical industry;

- Petroleum refineries;

- Thermal power plants;

- Paper and pulp industry;

Advantages of using Tubular Heat exchangers

Efficient heat transfer: Tubular heat exchangers enable an efficient heat transfer between two media through their designed tube bundles or coils. This results in fast and efficient heat transfer and minimizes energy losses.

Versatility: Tubular heat exchangers can be adapted to different applications and process requirements. They can be made with different materials, including carbon steel, stainless steel, duplex materials and titanium, to suit different process media and environments.

Low maintenance cost: They usually require minimal maintenance and have a long lifespan. This makes them cost-effective in the long run and helps to reduce downtime and loss of production.

Here is a list of Tubular Heat Exchangers with corrugated tubes offered by Erivac:

– Useful for the treatment of slurries and particulate liquids.

– Consists of two concentric tubes.

– Shell and tube heat exchangers with tube bundles developed for industrial applications.

– Used for heating water with steam, energy recovery, condensation, etc.

– Shell and tube heat exchangers with tube bundles for hygienic/sanitary applications.

– Used for heat recovery in the food, dairy and beverage industries.

– Tube-in-tube heat exchanger with corrugated tubes.

– Designed for direct regeneration between hot and cold sludge and biomass.

– Packaged systems for the production of clean steam.

– Used in the food and beverage, pharmaceutical, healthcare, biotechnology, electronics and brewing industries.

– A heat exchanger with a scraped surface.

– Suitable for treating liquids with high viscosity or high contamination.

Erivac offers a wide range of corrugated tube heat exchangers that can be adapted to specific applications and needs in different industries. These heat exchangers enable efficient heat transfer and are particularly suitable for treating different types of fluids and industrial processes.