Waste Water Aeration

Jet Aerators

Waste water aeration with increased efficiency Ejectors for waste water aeration - Jet Aerators

Advantages of Körting ejectors – Jet Aerators

- maintenance-free- no moving elements

- high oxygen efficiency- Fine bubbles create large contact surfaces between air and water and high turbulence renews these contact surfaces.

- no deposits- The intensive jet flow directed toward the tank floor prevents deposits of biomass.

- straightforward control of oxygen supply

- non-clogging construction – The nozzle diameter defines the narrowest flow cross-section.

- no sealing problems- When the plant is inactive, water can enter the air pipeline without negative effects and when re-started, the ejector’s entraining effect expels any liquid in the pipe.

- design acc. to requirements- Various sizes can be designed and adapted to requirements.

Jet Aeration - Ideal for plants with highly polluted waste water

In its construction form the ejector, jet aerator, for the aeration process corresponds to that of a jet ejector. Because organically polluted wastewater requires a high amount of oxygen and also because of the increasing height of modern biological wastewater cleaning plants it is energetically more efficient to pre-compress the air mechanically to the hydrostatic pressure prevailing at the installation point of the ejector, jet aerator, and to supply it so to the suction connection.

This waiving of an appreciable pressure in the ejector, jet aerator, reduces the necessary motive pressure. At the same time, more favourable mixing ratios (suction flow: motive flow) are achieved. Motive nozzles of Körting ejectors, jet aerators, are equipped with a non-clogging spiral. So the motive jet disperses the air already at a low motive pressure in a myriad of fine bubbles which are then mixed vigorously together with the motive flow in the mixing zone.

This air/water mixture is injected into the aeration tank with a high turbulence. In this way, the ejector, jet aerator, guarantees optimum oxygen supply and a total intermixing of the tank contents. Even with a high biomass concentration in the wastewater it is still possible to attain flow velocities that prevent deposits on the tank floor.

Multi-path ejectors, jet aerators, inside aeration tanks

Installation inside aeration tanks

Once the tank geometry, water depth and oxygen requirements have been determined then number, execution form and arrangement of the multi-path ejectors, jet aerators, can be adapted to the case in question. Their mounting can be effected quite simply by two flanges in the pipelines for motive flow and compressed air. Installation of compact units on the tank floor guarantees comprehensive jet aeration and complete intermixture of the waste water.

Design

The relatively short individual and detachable ejectors, jet aerators, are connected to a manifold casing and supplied with motive flow from below and with compressed air from above. The jet flow is inclined towards the floor and the angle of exit is adapted individually to the installation conditions. As material we use polypropylene which has excellent resistance to chemical attacks. For particularly demanding application conditions the motive nozzles as well as also the mixing zones can be made of chrome-nickel steel. When there are high calcium carbonate concentrations in the aeration tank the choice of materials must always be adapted to the operating conditions.

Oxygen efficiency

As oxygen transfer not only depends on bubble size (contact surface between gas and water) but to the same measure on the renewal of the gas bubble contact surfaces, ejectors – with their permanent circulation of the waste water – can so achieve a far larger oxygen efficiency than other aerators. With their inclined flow direction towards the floor Körting ejectors, jet aerators, utilise the respective tank depth completely as entrance depth. Extensive oxygen supply tests in pure water (ATV M-209) acc. to the oxygen adsorption method form the data basis for designing Körting ejectors, jet aerators. All measurements were executed on full-scale plants and confirmed in numerous inspection tests..

Control range and oxygen yield

Regulation of the oxygen supply is achieved solely by altering the air volume flow. A reduced air supply lowers the inlet pressure to the ejector thereby additionally reducing the power intake of the roots blower/compressor. At the same time the specific oxygen efficiency is increased. The result is a nearly constant high oxygen yield over the whole control range of the oxygen transfer system with its maximum value in partial load operation near the design point. Ejectors, jet aerators, are designed – depending on the rheological properties of the activated sludge (temperature, dry solids contents) – for a suitable air/water ratio. The improved performance of the oxygen transfer system by simply increasing the air supply as well as its optimal oxygen efficiency in partial load operation are so guaranteed at all times.

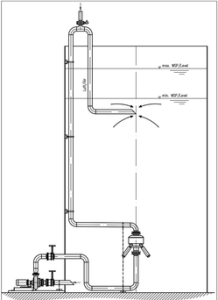

Installation from outside through the tank wall

The ejector, jet aerators, shown here is made of stainless steel and is mounted “through-the-wall“. Its connections for motive flow and compressed air are located outside the aeration tank. These comparatively large units are equipped with a second downstream mixing zone in which additional liquid is sucked in, thus intensifying the intermixing action in the tank.

If required, the ejector, jet aerator, can be equipped with a shut-off device downstream of the motive nozzle so that the motive nozzle can be checked at any time without having to empty the tank. This equipment option allows for a permanent application of the oxygen transfer system, even with extreme concentrations of calcium carbonate in the wastewater. Although the relatively large ejectors, jet aerators, are inferior regarding oxygen efficiency to our multi-path ejectors with finer air bubbles, their 100% availability is often the decisive criterion for our customers. It is therefore not remarkable that many plants have been realised in the paper industry – sometimes also as a retrofitting action to replace inadequate installations.

Oxygen efficiency

At the usual entrance depths of 5…8 m it is possible to achieve an oxygen efficiency OC20in clean water of 11 g O2/Nm3• m. In partial load operation – at a reduced air amount – the oxygen efficiency can be boosted above this value as far as 14 g O2/Nm3• m. Depending on entrance depth and oxygen requirements approx. 400-500 Nm3/h of compressed air can be injected into the tank by one single ejector, jet aerator.

Ejectors in SBR plants

Ejectors, jet aerators, are exceptionally suited for the aeration and intermixing of so-called „SBR“ plants (Sequenced Batch Reactor). These aeration plants (with retaining operation) in which, amongst other things, the biological processes of nitrification and denitrification take place consecutively in the same tank, require a complete intermixing of the tank contents with and without an air supply. Through the installation and special arrangement of ejectors, jet aerators, patented for this process in the SBR reactor they can be utilized for the simultaneous aeration of wastewater and intermixing during the aeration phase as well as for a selective circulation – without air supply – during the mixing phase.

Recirculation of the wastewater through the ejectors takes place automatically at the end of the aeration phase. Both phases can be alternated as often as required so that the independence of the wastewater treatment process from feed conditions realised in the SBR process will be supported.

The ejectors, jet aerators, responsible for completely intermixing the tank contents during the mixing phase, are operated with the same circulation pumps used during the aeration phase. When the ejectors convey liquids, the power intake of the circulation pumps is utilised to an optimum – even during the mixing phase..

SBR process will be supported.

The ejectors, eductors, responsible for completely intermixing the tank contents during the mixing phase, are operated with the same circulation pumps used during the aeration phase. When the ejectors convey liquids, the power intake of the circulation pumps is utilized to an optimum – even during the mixing phase..

Design according to requirements

The numerous layout and arrangement possibilities of ejectors and their differing operating methods with atmospheric air intake or compressed air provide ideal basic conditions for their application in large and small water treatment plants.